Upside down bottles, cans

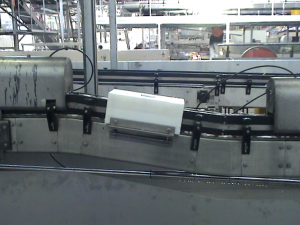

Milk powder cans are often filled upside down. Also, some ingenious sauce, syrup and honey bottles have the lid on the bottom for always-ready dispensing.

These are filled upside down and need to be inverted before boxing so that they arrive at the retailer ready for the shelf.

Rinsing

Perhaps the most common use is for Rinsing. Flipping containers upside down, and rinsing with air or water, ensures debris is cleaned out before filling.

Drying

Products that get wet during cooking or pasteurising are dried effectively if blown after being turned upside down.

Shelf ready packaging

Supermarkets are more demanding that products are delivered shelf ready. Products filled upside down need to be upended before packaging.